Giới thiệu:

Công ty TNHH MTV Khoáng Sản Vôi Việt chúng tôi chuyên sản xuất Xi măng thường PCB30 – PCB40, Xi măng bền Sun phát PCSR30 – PCSR40 (Xi măng chịu mặn).

Xi măng chịu mặn của Công ty được sản xuất từ công nghệ gốc không pha phụ gia, là sản phẩm xi măng chịu mặn đầu tiên được chứng nhận hợp chuẩn Quốc gia tại Việt nam năm 1999 theo tiêu chuẩn TCVN 6067 : 2004 và được chứng nhận phù hợp tiêu chuẩn ASTM C150 : 05 (tiêu chuẩn Mỹ), BS 4027 : 1996 (Tiêu chuẩn Anh).

Thương hiệu sản phẩm Xi măng của Vôi Việt bao gồm PCB30 – PCB40 và PCSR30 – PCSR40 đã được Bộ Khoa học Công nghệ công nhận là là loại Cement đặc biệt dùng ở các địa bàn ngập lụt, vùng nhiễm phèn, miền núi và Hải đảo, những vùng có ít điều kiện bảo dưỡng. Có cường độ ổn định, chống xâm thực, không rạn nứt. Phù hợp cho tất cả các công trình dân dung và công nghiệp các công trình giao thông thủy lợi, các công trinh hạ tang cơ sở, cũng như các công trình yêu cầu cường độ cao và phát triển sớm. Đặc biệt phù hợp với các kết cấu móng, dầm, cột, cầu đường, các cấu kiện bê tông khối lớn.

Có cường chịu nén chịu uốn cao, kết khối đặc chắc độ giãn nở co ngót thấp, đông kết nhanh, ổn định.

Có độ dẻo, độ linh động cao giúp quá trình thi công dễ dàng.

Chống xâm thực, bảo vệ cốt thép vĩnh cửu trước sự phá hủy của môi trường.

Chịu được sự tác động khắc nghiệt của môi trường Sun phát, Clo, axit, nước lợ, nước mặn, nước mưa.

Đặc biệt bền vững nếu dùng thi công phần móng và đổ mái công trình: Các công trình ngầm, bể chứa nước, bể phốt cho nhà ở, các công trình dân dung, công nghiệp.

Khả năng chịu sự thay đổi môi trường, chống co ngót, chống nứt, chống thấm cho các công trình xây dựng.

Thay thế cho tất cả các loại cement thông dung khác để xây dựng các công trình dân dung, công nghiệp.

Dễ thi công sử dung như các loại Cement thông dụng.

Chúng tôi xin cam kết cung cấp cho Quý khách sản phẩm Cement có chat lượng cao, đáp ứng đủ các chỉ tiêu, các tiêu chuẩn đã đăng ký.

Cam kết bảo hành sản phẩm, đảm bảo chất lượng công trình, nếu quá trình thi công đúng theo hướng dẫn và quy chuẩn xây dựng.

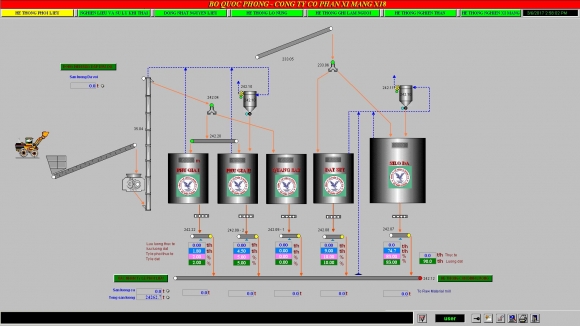

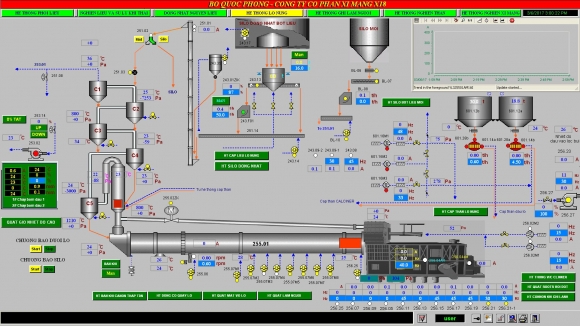

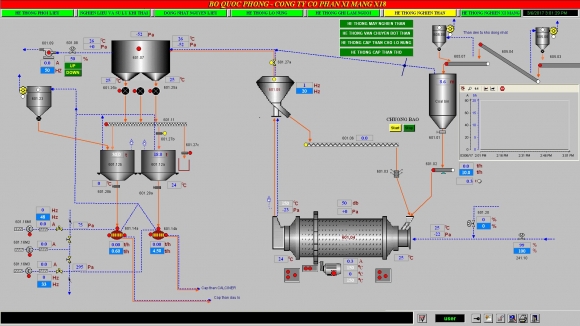

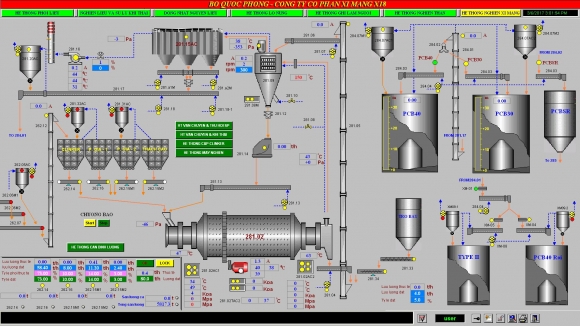

Sơ đồ quy trình sản xuất Xi Măng:

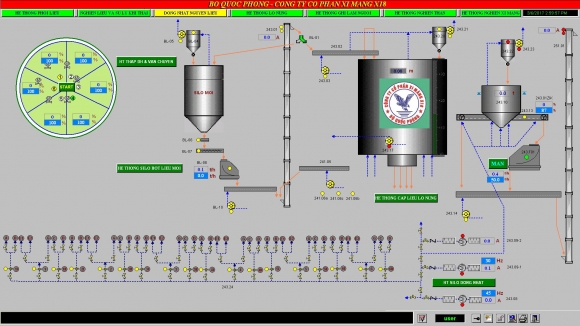

Hệ thống đồng nhất nguyên liệu:

Hệ thống phối liệu:

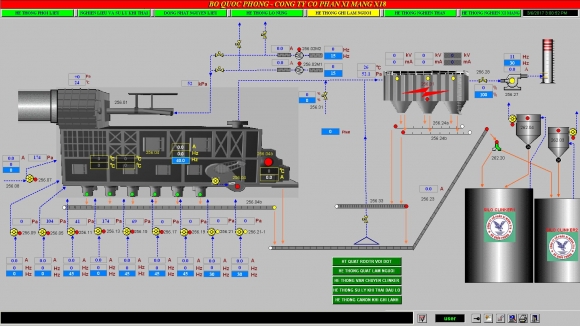

Hệ thống ghi làm nguội:

Hệ thống lò nung:

Hệ thống nghiền than:

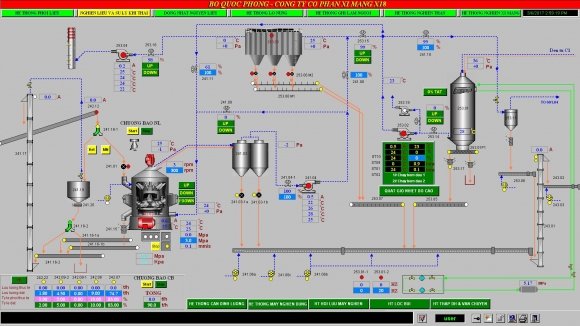

Hệ thống nghiền Xi măng:

Hệ thống nghiền liệu và xử lý khí thải: