Nguyên liệu:

– Than: Với hệ thống quạt gió mới cải tiến của lò liên hoàn cho phép sử dụng loại than bã sàng (lẫn lộn giữa than kíp và than bìa) nhiệt lượng 5400 kcal thay thế cho than kíp nhằm hạ giá thành sản phẩm. Nguồn cung ổn định tại Ninh Bình.

– Đá: Tại mỏ của công ty được tập kết bằng xe về bãi chứa tại nhà, hàm lượng CaCO3 98%, CaO 54% min, MgO 0.8% max, không tạp chất.

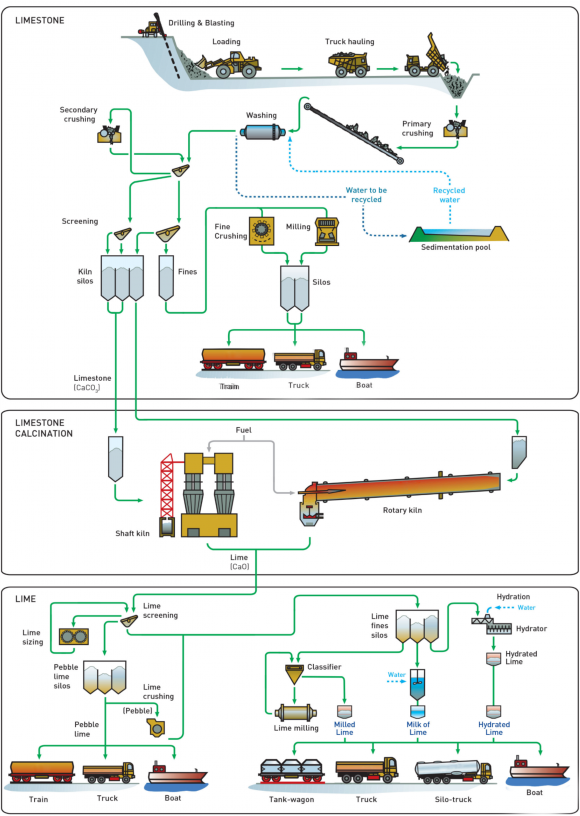

Quy trình sản xuất:

Sơ đồ quy trình sản xuất:

Quy trình sản xuất:

Than sau khi phân loại (loại bỏ than bìa và kíp to) được đưa lên phễu than bằng máy xúc lật. Từ phễu than được qua băng tải cân định lượng và xả vào gầu tải đưa lên mặt lò rải trực tiếp vào mặt lò.

Đá được sàng lọc tuyển chọn kích thuớc phù hợp (40- 80mm) qua gầu vận chuyển đưa lên lò.

Theo đặc tính của lò liên hoàn, khi ra lò tạo quá trình sụt lún, vật liệu dịch chuyển theo phương thẳng đứng từ trên xuống dưới. Sản phẩm lần lượt đi qua các vùng: SẤY – CHÁY – LÀM -NGUỘI . Không khí được quạt nhồi, kết hợp với chênh lệch áp suất tự nhiên đi từ dưới lên trên qua các khe hở vật liệu, cung cấp oxy cho sự cháy trong lò.

Quá trình phản ứng trong lò diễn ra như sau:

Ở độ cao 20m – 30m, vật liệu hỗn hợp than và đá mới nạp liên tục được sấy nóng từ 200-300 độ. Nước và các tạp chất đi cùng bị bốc hơi và cháy. Quá trình sụt lún, vật liệu tiếp tục đi xuống ở độ cao 10 đến 20m than bắt lửa và phản ứng với O2 tạo ra sự cháy. Nhiệt độ tại đây đạt 1000 đến 1200 độ. Đá vôi CaCO3 chuyển thành vôi canxit. Khi hạ xuống độ cao từ 0 đến 10m tính từ ghi lò. Than đã cháy hết tuy nhiên nhiệt độ ở đây còn tương đối cao khoảng 300 độ, không khí đi qua được sấy nóng tiếp tục cung cấp oxy cho sự cháy trong lò. Một vòng tuần hoàn của vật liệu từ khi vào tới khi ra lò là 35 tiếng.

Trong quá trình nung sẩy ra các phản ứng hóa học sau:

C + O2 to CO2 + Q

2C + O2 to 2CO + Q

2CO + O2 to 2CO2 + Q

CaCO 3 to CaO + CO2

Ngoài các phản ứng chính như trên còn có nhiều phản ứng hóa học khác cũng xẩy ra trong quá trình nung như SO2, NOx, MgO…

Sản phẩm khi ra lò đi qua băng tải trên đó bố trí sẵn công nhân tuyển lựa cuối băng tải vôi được đưa lên kẹp hàm và sàng phân loại kích thước hạt theo yêu cầu của khách hàng.

Vôi sau khi qua sàng phân loại tùy vào yêu cầu của từng khách hàng có thể lựa chọn đóng bao trực tiếp tại máy sàng phân loại hoặc đưa lên silo chứa dự trữ.

Hiện tại sản phẩm vôi công nghiệp do công ty chúng tôi sản xuất đạt chất lượng cực cao do sở hữu mỏ nguyên liệu đá chất lượng cao. Vôi sau khi ra lò đạt tiêu chuẩn thông số CaO 90% min, MgO max 1.5% ngoài ra các chỉ tiêu khác đều đáp ứng tất cả các nghành công nghiệp khó tính như thép, phân kim, sử lý môi trường…..